rate screw palm kernel oil press in rwanda

- Usage: Palmeed,palm,Palm etc.

- Type: oil press machinery

- Production Capacity: high

- Voltage: 220V, 220V/ OTHER

- Power(W): 7.5kw

- Dimension(L*W*H): 1950x1300x1900

- Weight: 1100kg

- After-sales Service Provided: No overseas service provided

- Product name: Palm Oil machine

- Application: oil press

- Warranty: One Year

- Material: Carbon Steel

- Feature: cold and hot press

- Function: screw

- Capacity: 80-600kg/h

- Model: 6YL

- Price: Negotiable

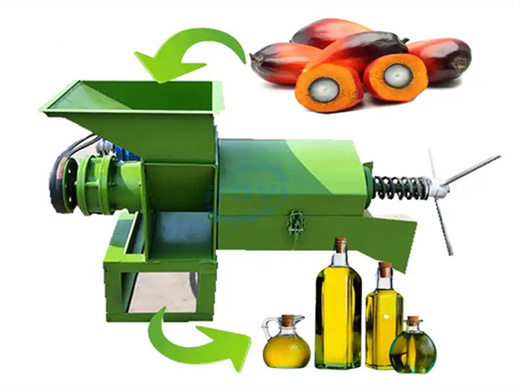

The machine design enables cold palm kernel seeds to be processed without pre-treatment, the breaking and cooking operation being performed by the action of the screw shaft within the barrel of

Subramaniam et al. (2013) specifically use the screw press technique to extract palm kernel oil. Ikechukwu et al., (2012) designed an expeller pilot plant to extract 200 kg of oil/day. The plant was tested with an initial input of 59.52 kg of palm kernel per hour, for 10 h. As a result, 200.05 kg of high-quality palm kernel oil was obtained.

Screw Palm Oil Press And Palm Oil Mill Machine Seed Oil Pressing Machine

- Usage: Palm Oil

- Type: Palm Oil Processing Machine, Palm Oil Processing Machine

- Production Capacity: according to the capacity

- Voltage: according to the capacity

- Weight: 1000 KG

- Warranty: 1 Year

- Key Selling Points: Automatic

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Engine, Gearbox

- Product name: Oli Press Machine

- Raw material: Palm, Palm Kernel

- Keyword: Seeds Oil Pressing Machine

- After-sales Service Provided: Service Machinery Overseas

- Used for: Large Scae Oil Refining Plant

- Advantage: Simple Operation

- Extraction of Oilseeds: Palm

- Oilseeds: Palm

- Function: Refining Vegetable Oil

Palm Oil Press Station: Separate palm fruit and kernel, and palm oil press machine can obtain CPO (crude palm oil) and palm kernel. The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production. Palm fruits through elevator and conveyors, enters into upper steaming boiler of oil

The average palm kernel oil extraction rate is 45.63% and Figure 8 shows the palm kernel oil extraction rate trend in Malaysia (MPOB, 2021). Figure 6. Typical filter press structure for crude palm kernel oil clarification. Load cells Moving head Filter cloth support upper rails Cloth wash spray bars Fixed head Parallel hydraulix cylinders

Development of a Screw Press for Palm Oil Extraction

- Usage: Palm Oil

- Production Capacity: 500kg/h

- Voltage: 380V/diesel

- Weight: 280 KG

- Warranty: 1 Year

- Key Selling Points: press palm oil

- Marketing Type: Ordinary Product

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- production name: oil press machine for palm fruit

- keyword1: palm oil milling and pressing machine

- keyword2: 1-2t/h palm oil press line

- Raw material: Palm, Palm Kernel

- Function: to extract palm oil CPO from palm fruit

- Certification: CE/ISO

- Method to press: physical

- Application range: palm oil factory, home use

- After-sales Service: Technology Supporting

- Color: as required

The highest oil extraction ratio (OER) of 17.90% and oil extraction efficiency (OEE) of 79.56% were obtained at the sterilization time of 60 min, digestion time of 10 min and screw speed of 10 rpm.

The screw press is adjudged suitable for palm kernel oil extraction. based on its OEE. The ANOVA of the results show that the best kernel factors for highest OEE include KMC of 5% w.b.; KHT of 50

Effect of some kernel factors on palm kernel oil extraction

- Usage: Palm Oil

- Type: Automatic Palm Fruit Oil Processing Machine

- Production Capacity: 20kg/h

- Voltage: 220V/single phase

- Dimension(L*W*H): 70x40x90cm

- Weight: 60 KG

- Warranty: 1 Year

- Key Selling Points: Multifunctional

- Machinery Test Report: Not Available

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor

- After-sales Service Provided: Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

- Item: commercial Palm oil extractor machine

- capacity: 20kg/h

- input dia: less than 5mm

- moisture: about 4%

- motor: electric motor

- Raw material: Palm, Palm Kernel

- package: wooden case

- After Warranty Service: Video technical support, Online support, Spare parts

- Local Service Location: None

- Certification: CE

in the screw press. Palm kernel screw press MS 鈥?100) fabricated by (Magnus (Nigeria) was used for the oil extraction. The press has a capacity of about 101.7 kg h-1. at a speed of 56 rpm, powered by a 45 kW, 3 phase electric motor. The screw press had a test run for about 2 min before loading and processing the conditioned samples. The expressed

The mass flow rate data collection system will be able to notify the user when the screw press machine has reached a critical point for maintenance and also help in the troubleshooting process to locate the source of the decrease in performance of the screw press.

Effects of some kernel factors on palm kernel oil

- Usage: Palm Oil

- Production Capacity: 100-600kg/h

- Voltage: 220V

- Dimension(L*W*H): 2000*1500*1720MM

- Weight: 760KG

- Warranty: 1 Year

- After-sales Service Provided: Field maintenance and repair service, Video technical support

- Raw material: Palm, Palm Kernel

- Name: Palm oil production line

- Used for: Palm s

- Feature: High Oil Yield Efficiency

- Advantage: Energy Saving

- Delivery: 30 Working Days

- Function: Press Oil Seeds

- Color: Silver

- Shipping: Sea

- Certification: ISO

The kernels were finally put into randomly-numbered and labeled containers (3-litre buckets) ready for processing in the screw press. Palm kernel screw press (MS 鈥?100) fabricated by Magnus (Nigeria) was used for the oil extraction. The press has a capacity of about 101.7 kg h-1 at a speed of 56 rpm, powered by a 45 kW, 3 phase electric motor.

reviews few variables that affect the screw press operation performance. INTRODUCTION Screw press operation is one of the most important processes in palm oil mill. It is responsible for extracting oil from digested mesocarp with consideration of the following objectives, minimum oil loss in pressed fibre and minimum nut breakage at

- What is screw press operation in palm oil mill?

- Screw press operation is one of the most important processes in palm oil mill. It is responsible for extracting oil from digested mesocarp with consideration of the following objectives, minimum oil loss in pressed fibre and minimum nut breakage at the designated press throughput.

- What is the operation of palm oil pressing station?

- The overall operation of pressing station consists of digestion, pressing, dilution and screening. In conventional palm oil mill, the fruits, so called (MPD) mass passing to digester are digested at 90oC for about 20 min. For a 15 t throughput press, typical volume of the digester is about 3500 litres.

- What is the optimum nut to fibre ratio for screw press operation?

- Previous study shows that the optimum nut to fibre ratio for screw press operation is 45:55 (Lokman, 2003). Sterilisation is a crucial process that if not properly carried out will affect most of the downstream processes during palm oil milling (Figure 1). Sterilisation helps in loosening the fibre from the nuts during pressing operation.

- How a palm oil mill works?

- In conventional palm oil mill, the fruits, so called (MPD) mass passing to digester are digested at 90oC for about 20 min. For a 15 t throughput press, typical volume of the digester is about 3500 litres. During digestion, the oil-bearing cells are ruptured and this will facilitate oil extraction during pressing and clarification.