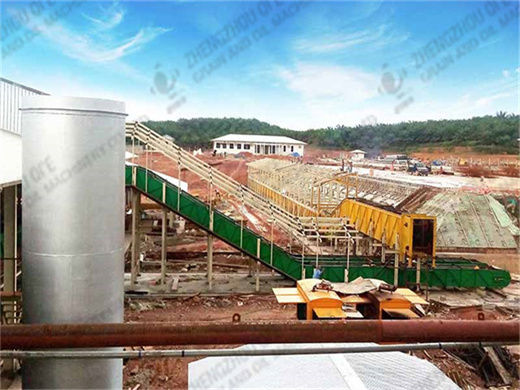

palm kernel oil solvent extraction plc system

- Usage: Palm Oil

- Production Capacity: 100%

- Voltage: 380V

- Dimension(L*W*H): according to the capacity

- Weight: 90000 KG

- Warranty: 1 Year

- Key Selling Points: Long Service Life

- Machinery Test Report: Not Available

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Pump

- Product name: palm oil processing equipment

- Brand: Hongyang

- Material: Stainess Steel and carbon steel

- Application: Palm oil plants and food industry

- Raw material: Palm, Palm Kernel

- Advantage: Energy Saving Low Residual

- After-sales Service: Engineers AvailableToService Machinery Overseas

PKO extracted with co-solvent systems had better quality characteristics compared with single solvent extracts. The oil recovered, free fatty acid content, peroxide value and other quality characteristics, and thermal properties were within the range for PKO, and similar oils as stipulated in standards.

The oil yield of 34.2% was obtained in the extraction condition of the ratio of palm kernel to ethyl acetate of 1:7, the rotational speed of 5000 rpm, and 10 minutes extraction time.

KROHNE | Palm kernel processing - Palm oil production

- Type: Textile Waste Recycling Line

- Voltage: 380V

- Power: 22kw

- Weight: 700kgs

- Dimension(L*W*H): 1200*1500*1150mm

- Warranty: 1 Year

- After Warranty Service: Video technical support

- Local Service Location: None

- After-sales Service Provided: Video technical support, Engineers available to service machinery overseas

- Certification: CE

- certification: alibaba depth authenticaon

- colour: green, white or any colour

During the oil extraction, the vegetable oil is removed from the cell structure using a solvent, usually n-hexane, which is a volatile and inflammable liquid. In order to enable the solvent to penetrate unhindered into the seed, the cell walls have to be broken up and the diffusion paths have to be made as short as possible.

The plot of 1/y (ie, 1/yield) against 1/t, gives intercept as C 2 /C 1 and slope as 1/C 1. 2.3.2 Pseudo-second order model The second-order rate law had been used over the years to model solvent extraction of a number of substances from plants, leaves, seeds,

DIFFUSION RATE ANALYSIS IN PALM KERNEL OIL EXTRACTION USING DIFFERENT EXTRACTION SOLVENTS

- Model Number: HT300

- Impact Drill Head: Impact Drill

- Drill shape: Round

- Usage: Drilling Under Pressure

- Suit Pipe Material: Steel / Ductile Iron / Cast Iron / Plastic Pipe

- Suit Pipe Medium: Water, Gas , Oil. Steam

- Tapping Range: 4′′-12′′

- Motor: 380V, 1.5kw

- Pressure/Flange: Pn10, Pn16, Pn25

- Feed Mode: Electric Manual

- Feed Volume: 0.07-0.2 mm/R

- Working Stroke: 600mm

- Spindle Speed: 40 Rpm

- Motor Power: 220V, 1.5kw

- Tapping Time: 15-30 Min

- Transport Package: Wooden Case

- HS Code: 8467210000

This study investigated the rate of diffusion on the extraction of palm kernel oil using various solvents, namely, n-hexane, Benzene, Trichloroethylene, and Carbon disulfide. The solvents and the

Oleic acid contents of safflower oils extracted by hot extraction system was ranged between 41.20% (acetone) and 42.54% (hexane), its content in oils obtained by cold extraction method was varied

Mathematical Modeling of the Solvent Extraction of Palm Kernel Oil from Palm Kernel

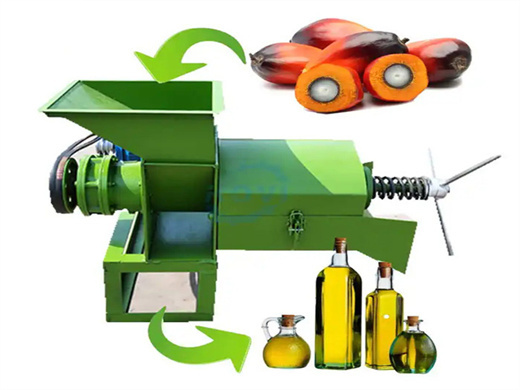

- Usage: Press Oil

- Type: Reasonable Price Hot Sale Oil Press Palm Oil Press Machine

- Production Capacity: 10tpd, 100tpd, 1000tpd

- Voltage: 380V/50HZ

- Dimension(L*W*H): 270*260*350*60mm

- Weight: 3KG

- Warranty: 1 Year

- Key Selling Points: Energy saving

- Machinery Test Report: Provided

- Video outgoing-inspection: Provided

- Warranty of core components: 1 Year

- Core Components: Motor, Engine

- Name: manual oil press machine

- Raw material: Palm, Palm Kernel

- Material: Stainless Steel 304

- Function: Making Palm Oil

- Color: Custom-made

- Advantage: Energy Saving

- Product capacity: 1-2kg/h

- Package size: 42*8*32cm

- Automatic Grade:: Manual

- Product name: Oli Press Machine

- After Warranty Service: Video technical support, Online support

- Local Service Location: None

- After-sales Service Provided: Video technical support, Online support

- Certification: CE ISO

Mathematical Modeling of the Solvent Extraction of Palm Kernel Oil from Palm Kernel leached and by decreased radial distance that must be traversed within the solid, both of which are favoured by decreased particle size (Perry et al., 2003).

The efficiency of isopropanol in extracting oil from PKC was first compared with that of hexane using SE at an extraction temperature of 150 C. Fig. 1 compares the oil yields from PKC with the particle size in a range of 0.7–2.0 mm (SE-150 C, PKC-size 0.7–2.0 mm) and PKC with the particle sizes below 0.7 mm (SE–150 C, PKC-size < 0.7 mm).

Comparison of solvent systems on extraction, quality characteristics, and volatile compounds of palm kernel oil - Semantic Scholar

- Usage: Palm processing machine

- Type: Palm oil,Palm processing machine

- Production Capacity: 30kg-30t/day

- Model Number: Cooking oil solvent extraction machine

- Voltage: 380V or designed by your needs

- Power(W): Depend on the machine you choose

- Dimension(L*W*H): Depend on the machine you choose

- Weight: Depend on the machine you choose

- Certification: CE and ISO

- Item: Cooking oil solvent extraction machine

- Supplier type: 20 years Manufacturer

- Steel type: MiId steel and SS

- Add chemical material: n-hexane

- Raw materials: Palm s,Palm, Palm

- Fina product: Salad oil

- Processing method: Machanical press

- Handling capacity: according to custoemer design

- Model type: Continuous

- Main market: Africa, Aisa

Hexane (HEX) and dichloromethane (DCM) have been used to extract oils from various sources due to their expansive solubility and low volatility that ease removal at low temperatures. However, environmental and health concerns make them undesirable solvents. The aim of this study was to evaluate the extraction efficiency and physicochemical characteristics of palm kernel oil (PKO) extracted

The total FFB and crude palm oil (CPO) production for January and December 2010 was 74.5 million tonnes and 15.4 million tonnes, respectively. A total of 3.9 million tonnes of palm kernel oil (PKO) was produced during the same corresponding period. In the case of Indonesia, the industry has grown rapidly with the oil palm plantation expanding

- What is palm kernel oil extraction & refining?

- Palm kernel oil (PKO) extraction and refining techniques involves operations such as sorting of kernels, handling, mechanical pressing, filtration of crude oil, thermal, chemical and physical treatment of crude oil to obtain desired edible oil that suits variety of applications.

- What solvent is used to extract Palm oil?

- The extraction of oil was performed using n-hexane, methanol, ethanol, and toluene as an extraction solvent. The required chemicals were purchased from Merck and Sigma Aldrich, Malaysia. The POME sample was collected from Felcra Nasaruddin Palm Oil Mill located in Perak, Malaysia.

- Which organic solvent is used to extract oil from palm oil mill effluent?

- The parametric study of the oil extraction from palm oil mill effluent (POME) has never been done before. Therefore, four organic solvents including n-hexane, methanol, ethanol, and toluene were used in soxhlet extraction to extract the oil.

- What is the extraction rate of palm oil?

- The typical crude palm oil extraction rate (OER) during the milling process is in the region of 18¨C23% by weight to FFB, while the palm kernel extraction rate (KER) ranges between 4 and 6%. The simplified palm oil extraction process is shown in Fig. 8.3. The basic quality parameters for palm products are tabulated in Table 8-B. Fig. 8.3.